As Vermont’s traditional dairy industry collapses, a new generation of farmer-scientists is thinking small — very, very small

By Claude Milquetoast, Rural Affairs Correspondent

HARDWICK, Vt. — On a frigid December morning, Eldon Thibodeau stands in his converted pole barn, watching a parade of cows no larger than border collies trundle past on a rubberized conveyor belt toward the milking station. The animals, which he calls “Pocket Holsteins,” regard him with enormous, gentle eyes set in heads the size of cantaloupes.

“People said I was crazy,” Mr. Thibodeau said, adjusting a tiny stanchion. “But look at the math. These girls give two-thirds the milk of a standard Holstein on less than a quarter of the feed. I can run 200 head in a barn that used to hold 40.”

The math, indeed, has become existential for Vermont dairy farmers. In 2012, the state boasted roughly 900 dairy operations. Today, fewer than 500 remain. Last month, Waterbury lost its final three dairy farms, a closure that prompted one selectboard member to observe, simply, “There goes the neighborhood.”

But in corners of the Green Mountain State, a quiet revolution is underway — one that asks not how to make dairy farming bigger, but how to make it radically, almost absurdly, smaller.

The Incredible Shrinking Cow

Mr. Thibodeau, 58, spent 15 years selectively breeding his herd for diminutive stature, crossing Dexters with Jerseys with a Finnish breed he will identify only as “proprietary.” The result is a 140-pound dairy cow that produces approximately 35 pounds of milk daily.

“The conveyor belt was my wife’s idea,” he admitted. “We were losing too much time walking them to the parlor. Now they just hop on, ride through, and hop off into the pasture. It’s like a very slow, very productive amusement park.”

The milk, he said, is indistinguishable from conventional dairy, though one local cheesemaker claims it produces a sharper cheddar. Mr. Thibodeau has a waiting list of 47 farmers seeking his breeding stock.

“The only downside,” he added, watching a cow roughly the size of a beagle disappear through a pet door into the pasture, “is the eagles. We’ve had to net the whole operation.”

Going Rodent

Forty miles to the south, in a repurposed chicken coop outside Montpelier, Gerald Batchelder has taken the concept of miniaturization to what he acknowledges is “its logical, if uncomfortable, extreme.”

Mr. Batchelder milks voles.

“Meadow voles, specifically,” he said, gesturing toward a climate-controlled facility housing approximately 3,000 of the small rodents in stacked habitats. “They’re docile, they breed prolifically, and contrary to what you might assume, they’re actually quite cooperative once they understand the routine.”

The operation was not, he conceded, without a learning curve.

“I started with tweezers,” Mr. Batchelder said, wincing at the memory. “That was a long winter. But necessity is the mother of invention.” He displayed a device resembling a tiny medical apparatus: a miniature milking machine with suction cups the diameter of pencil erasers, capable of processing 12 voles simultaneously.

Each vole produces roughly a teaspoon of milk per session. With three sessions daily across his herd, Mr. Batchelder generates approximately four gallons per day — modest by conventional standards, but achieved at a fraction of traditional operating costs.

“Feed is negligible. Veterinary costs are negligible. Housing is just stacked plastic bins with bedding,” he said.

The milk itself presents unique characteristics. Mr. Batchelder has found a niche market among experimental cheesemakers and, intriguingly, a craft ice cream producer in Burlington who uses it for a high-end product called “Vole de Crème.”

The voles’ prolific breeding — females can produce up to 10 litters annually — initially posed a population management challenge. Mr. Batchelder has since partnered with a pet food company and three falconers, and recently launched a side business selling frozen “Vermont Heritage Rodent Stew” to adventurous locavores and raw-diet dog owners.

“It’s nose-to-tail, really,” he said. “Nothing goes to waste. The sustainability people love it, once they get past the initial squeamishness.”

The Microbial Frontier

If Mr. Batchelder represents one extreme of the small-dairy movement, then Dr. Ellen Rousseau has pushed beyond extremity into the genuinely microscopic.

In a converted sugarhouse in Cabot, Dr. Rousseau — who holds a doctorate in biochemistry from the University of Vermont and describes herself as “a farmer in the truest sense, just at a different scale” — produces milk proteins using genetically modified yeast.

“Saccharomyces cerevisiae,” she said, tapping a stainless steel bioreactor that hummed quietly in the corner. “Baker’s yeast. I’ve engineered strains that secrete casein and whey proteins directly into the growth medium. No udders required.”

The process, known as precision fermentation, has attracted significant venture capital interest in recent years. But Dr. Rousseau is focused on something more modest: a small-batch, artisanal approach she believes could work for individual farmers.

“My yeasts produce about 40 grams of protein per liter of culture,” she said. “Scale that up to a few hundred liters, and you’ve got the protein equivalent of a small dairy — in a space the size of a garden shed.”

Her latest breakthrough, achieved just this fall, involves a secondary yeast strain engineered to synthesize milk fats.

“Butterfat was the hard part,” she admitted. “Getting yeast to produce triglycerides in the right configuration took me three years. But I cracked it in September.” She held up a small jar of yellowish substance with evident pride. “Yeast butter. It’s not quite Land O’Lakes, but it melts.”

Dr. Rousseau acknowledged that regulatory questions remain unresolved. The FDA has not yet established a clear pathway for yeast-derived dairy products to be labeled as milk, a situation she called “bureaucratically frustrating but not insurmountable.”

“My yeasts don’t need pasture,” she said. “They don’t need veterinarians. They don’t produce methane. They just need sugar, warmth, and time. If that’s not farming, I don’t know what is.”

Academic Assessment

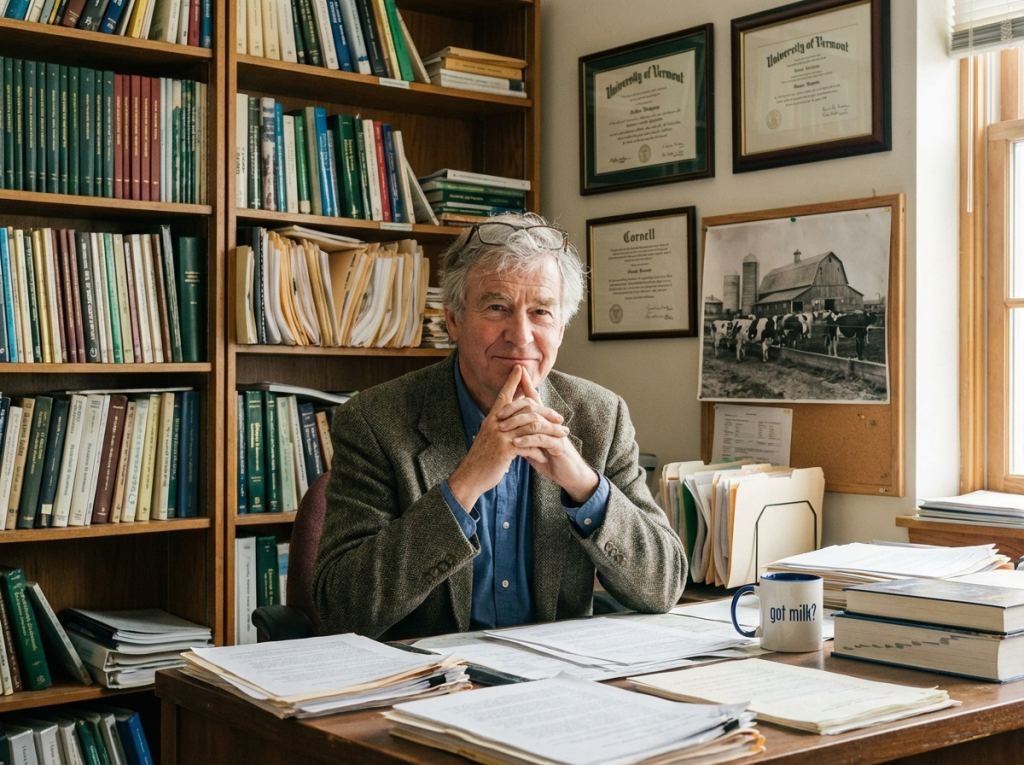

Dr. Richard Stanton, a professor of agricultural innovation at the University of Vermont, said the approaches represented by Mr. Thibodeau, Mr. Batchelder, and Dr. Rousseau reflect broader trends in American agriculture.

“We’re witnessing a bifurcation,” Dr. Stanton said in a telephone interview. “On one side, you have continued consolidation into massive operations. On the other, you have what I’d call ‘radical miniaturization’ — farmers who’ve looked at the economics and decided that the only way forward is dramatically downward.”

He expressed measured optimism about the miniature cattle, professional skepticism about the voles, and genuine intrigue regarding the yeast.

“The Pocket Holsteins are essentially a logical extension of existing breeding practices,” he said. “The rodent operation is, frankly, something I’d need to see to fully evaluate, and I’m not certain I want to. But the precision fermentation work is genuinely fascinating from a food-systems perspective.”

Dr. Stanton noted that none of these approaches would reverse the fundamental economic pressures driving dairy consolidation. “But they might,” he allowed, “represent viable niches for certain producers. Vermont has always attracted iconoclasts.”

Opposition Mounts

Not everyone in Vermont’s agricultural community has embraced the new approaches. Wayne Perkins, founder of the advocacy group Real Cows for Real Vermont, has organized opposition to what he calls “the miniaturization menace.”

“This isn’t dairy farming,” Mr. Perkins said, standing outside a conventional operation in Addison County where full-sized Holsteins grazed in a snow-dusted pasture. “This is — I don’t even know what this is. Science projects. Rodent husbandry. Witchcraft in a sugarhouse.”

Mr. Perkins’s group has lobbied state legislators to establish legal definitions of “milk” and “dairy farming” that would exclude products from animals under 200 pounds and any substance produced by single-celled organisms. Excluding, of course, bread, beer, and other alcoholic products.

“When my grandfather milked cows, he milked cows,” Mr. Perkins said. “Not hamsters. Not beer yeast. Cows. There’s a tradition here that matters.”

He acknowledged that his own 60-head operation has struggled financially in recent years. Asked whether he had considered any of the alternative approaches, he stared silently at the horizon for several seconds.

“I’d sooner,” he finally said, “milk a moose.”

Looking Forward

Back in Hardwick, Mr. Thibodeau watched his miniature herd return from pasture, filing through the pet door in an orderly procession as the winter sun began to set.

“People ask me if this is really farming,” he said. “I tell them: I wake up at 4 a.m. I shovel manure — less of it, granted, but manure. My hands smell like milk. My boots smell like hay. My wife says I talk about feed conversion ratios in my sleep.”

He bent down to scratch a Pocket Holstein behind its diminutive ears. The animal leaned into his hand with evident pleasure.

“If that’s not farming,” Eldon Thibodeau said, “I don’t know what is.”

Claude Milquetoast covers rural affairs and agricultural innovation for this publication. His previous work includes “The Rise of the Suburban Chicken” and “Goat Yoga: A Reckoning.”

Leave a Reply